Frame Business Division

Realizes integrated production, and uses know-how to realize low costs and short delivery times

Standardizes know-how gained over many years of designing, manufacturing, and constructing machinery covers to realize low costs and short delivery times. Has know-how in all industries, ranging from various industrial machinery to measuring equipment, semiconductor devices and equipment, and medical devices and equipment.

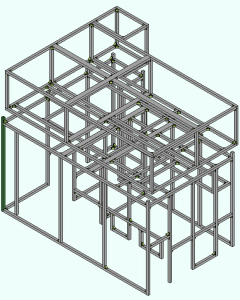

3D design

Establishes system creation that does not generate errors by using 3D drawings anyone can easily understand, even of hand-crafted complex shapes, created early on via 3D design based on 2D drawings from customers.

The merits of 3D design are accurately reflected in costs because it achieves more accurate product quantities, which makes it a factor in cost reduction.

Major manufacturing history

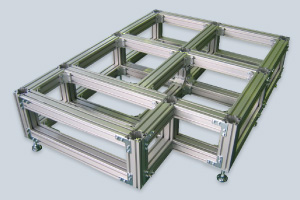

Safety covers(aluminum frames)

■ Can be assembled using bolts alone, and are lightweight

■ Realize short delivery times because welding, plating, and painting are unnecessary

■ Able to flexibly support design changes or expansions

Safety covers(Steel pipe)

When producing device covers from steel pipe, paint baking is started after attaching and checking all parts after frame welding to keep post-painting scratches to a minimum.

Safety covers(Stainless steel)

Safety covers made from stainless steel pipe are required for machines that handle food-related products, water, solvents, or chemicals on production lines.

-

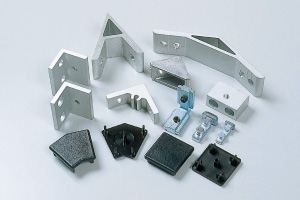

Handles, hinges, magnets

Able to support individual user specifications

-

Aluminum connecting parts and end surfaces

Frame structures can be integrated by sharing various blankets, etc.

-

Frame samples